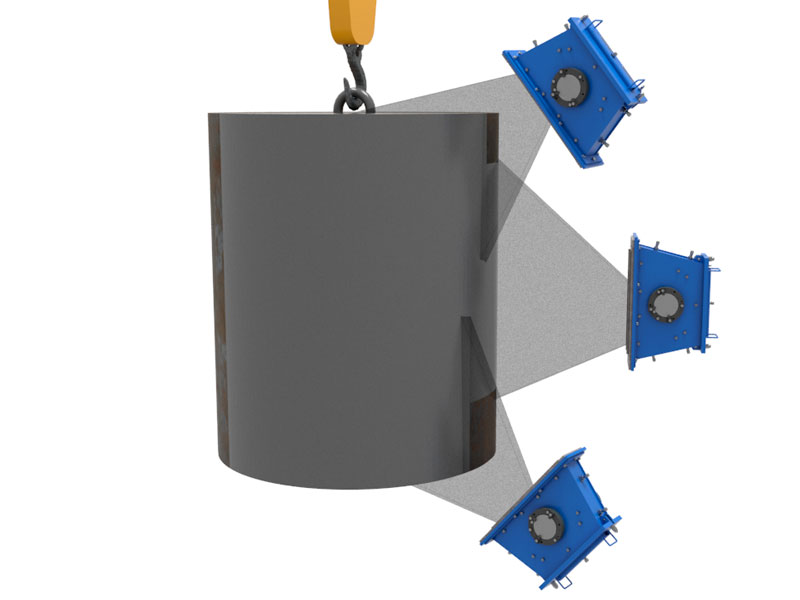

Overhead rail conveyor shot blasting machine

The required configuration of the shot blasting plant is determined depending on the specifications of the processed items, required performance, and production conditions of the customer.

Versions:

- terminal;

- through-type;

- Y-shape rails;

- with closed transport system.

Application

- Shot blasting from rust, scale and burrs of castings, forgings, moldings of medium and large sizes;

- Shot blasting of parts from molding sand;

- Giving the required roughness to the products;

- Preparation of the products before painting.

Operation principle

The parts are suspended with a workshop crane on the technological suspension. Technological suspension with the parts is risen to the upper position and is fed by the transport system into the chamber. The operator controls the lifting and moving of the suspension using a portable control console. At the operator’s command, the gate wings are pneumatically actuated and locked against accidental opening by manual locks.Then, shot blasting is performed in automatic mode. After stopping the shot blasters, the operator opens the manual locks and gives a command to open the door wings and move the suspension from the chamber. The suspension leaves the chamber, stops in the unloading area and comes down to the lower position for inspection of the parts and unloading. Then the cycle of the shot-blasting chamber operation is repeated.

The cleaning time is determined empirically and can vary from 1 to 5 minutes.

Specifications:

|

No |

Index |

DP-1700 |

DP-2100 |

DP-2500 |

|

1. |

Suspension capacity, kg |

1000 |

3000 |

5000 |

|

2. |

Max dimensions of workpieces to be cleaned, mm |

|

|

|

|

Diameter |

1300 |

1300 |

2500 |

|

|

Height |

1700 |

2100 |

2500 |

|

|

3. |

Quantity and power of shotblasters, kW |

2х11 |

2х15 |

3х18 |

|

4. |

Exhaust air volume, m3/hour |

4500 |

8000 |

14000 |